Projects

Yeast Drying Study

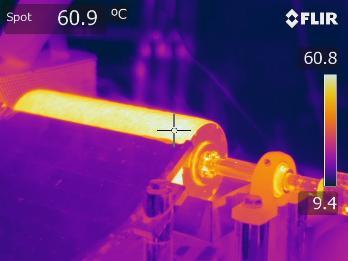

A prototype freeze drier was modified using funds from the grant to act as a drum heater/drier. This was used to test hypotheis that dried spent yeast could be used as animal feed.

A number of differnt parameters were modified during the trails to optimise the process; including drum roational speed, heating reservoir temperature and the angle and height of the cutting blade. Varying these conditions we were able to ensure the yeast cells were deactivated and would be suitable to use as a supplement in animal feed.

Grain Drying Study

A Cider Press was purchased using the funds from the grant to investigate the calorific value of spent brewers grain as a fuel source. The process involved pressing the grains to reduce their moisture content and then analysing the calorific value using a bomb calorimeter. The pressing liquor was also collected and analyses for Biochemical Methane Potential (BMP)

This project has shown there is a potential operating model whereby wet spent grain can be pressed, with the extracted liquor used for anaerobic digestion, and the fibrous solid fraction can be further dried for combustion or still utiised for animal feed.

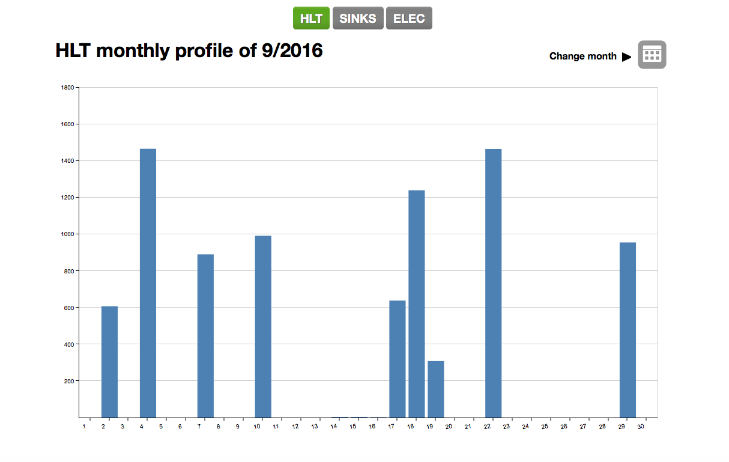

Assessing Water and Energy Use

This project focussed on assessing water and energy usage data using the brewery's meter logger and observation of tasks being performed in the brewery. A number of key events were identified through analysis of the data and improvements to working habits have been implemented to reduce the frequency of these events which can have a significant impact on total water useage.

Analysis of the Performance of Cleaning Procedures

The purpose of this project was analysis of the performance of the various cleaning procedures that are currently being used in the Stu Brew microbrewery.

The IfS grant provided funding to aquire a Luminometer and some ATP single use test so that we could quantify the effectiveness of current cleaning methods employed on site. It also allowed for the purchsase of Stainless Steel 304 and 316 samples that were used alongside an existing CIP prototype rig to examine the impact of reducing the concentrations of chemicals used. Early results have indicated that the concetrations can of NaOH can be reduced without a detrimental impact on the cleaning performance.