PROGRAMME AND METHODOLOGY

The overall aim of the project is to resolve the principal material issues required to allow the near term implementation of CO2 transport, and thereby of CCS itself. Addressing these issues is critical to the safe, economic and efficient design of a CO2 transport infrastructure within an environmentally responsible framework.

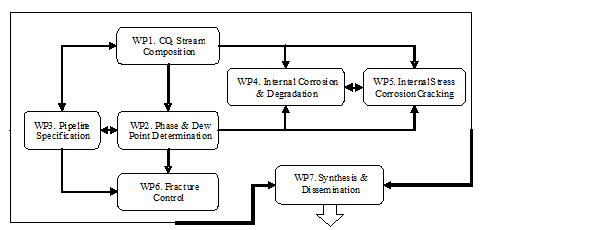

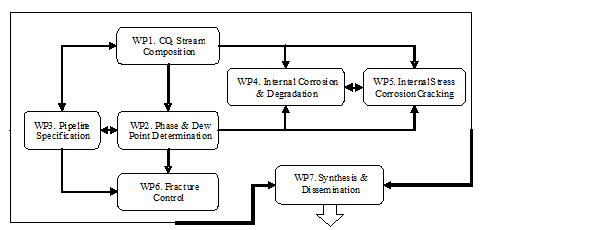

In this project, the key materials issues that will be addressed are corrosion, degradation and internal stress corrosion cracking of pipeline and associated equipment materials in the CO2 stream and fracture propagation behaviour in the event of a release from the pipeline. Addressing these issues requires a definition of the CO2 process stream and the ability to predict the behaviour of that stream under both typical and atypical operating conditions. The sub-aims of the project are therefore to define and predict the conditions under which corrosion, degradation and internal cracking will occur; to validate these predictions with experimentation and modelling; and to specify the material properties and/or CO2 stream composition required to prevent or control corrosion, degradation, cracking and fracture propagation. MATTRAN will achieve these aims through seven inter-related work packages, as defined in the flow chart of Figure 1, with the following objectives:

Figure 1: Project Overview Flow Diagram

WORK PACKAGE DESCRIPTION AND METHODOLOGY

The objectives described above have been integrated into the individual work packages to define the outputs and deliverables from each work package. The links on the left describe the work packages, the interactions between each of the work packages and the aims and outcomes.

OBJECTIVES

- To produce a definition of the acceptable constituents, and their levels, that could be present in the CO2 process stream from a legislative, economic and operational view point (WP1).

- To conduct phase behaviour experiments for CO2 and other component gas mixtures as defined in WP1 to allow the validation of existing phase and hydraulic models (WP2).

- To develop a mathematical model for predicting the phase behaviour and associated fluid properties of CO2 (WP2).

- To conduct dew point experiments for CO2 and other component gas mixture to define drying specifications for the CO2 stream (WP2).

- To validate current pipeline hydraulic models and/or develop alternate approaches using the results of WP1 and WP2 and develop a CO2 pipeline quality specification (WP3).

- To extend the experimental database for CO2 streams for a range of pipeline and compressor materials and to investigate the role of inhibitors in controlling corrosion during plant upset conditions (WP4).

- To conduct exposure testing of elastomers in supercritical CO2 streams to determine their suitability for this service (WP4).

- To confirm whether environmental cracking is a threat to pipeline and compressor materials in CCS service, and, if it is, to determine the limiting conditions of stress, composition and temperature required to prevent cracking (WP5).

- To develop and experimentally validate a mathematical model for the prediction of the risk of running fractures in CO2 pipelines (WP6).

- To define the material and operational procedures required to prevent and control fracture propagation in pipelines in the event of a release (WP6).

- To synthesise and disseminate the results of the research in a timely manner to key stakeholders to allow rapid implementation of the outcomes of the project (WP7).