Research

Work package 1: Polymeric membranes

Work package 2: Hybrid membranes

Work package 3: Ceramic membranes

Work package 4: Membrane characterisation

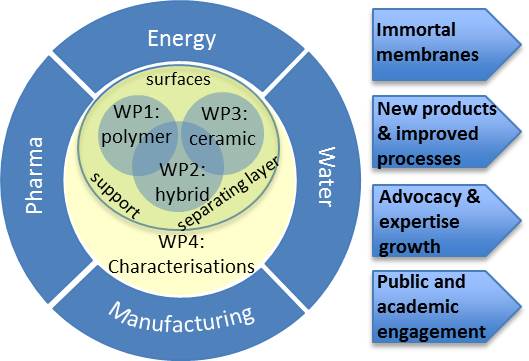

Inter-relationship between WP1, WP2, WP3 and WP4: Synergies will also arise from the development ofadvanced and shared characterisation techniques(see Figure 4) as well as our philosophy forevaluating membranes operated under operating conditions for significant durations. Again allinvestigators are involved in WP4. Crucially, results from such long term operation will beanalysed and used to inform the projects occurring within the other WPs. We will combine theindividual groups’ signature platforms for materials synthesis and membrane fabrication to createbreakthrough membranes with unparalleled robustness, as measured for key applications:

Energy: Both hydrogen and carbon dioxide removal from water-gas shift reaction environments (H2/CO2) at low (100-200°C), moderate (300-400°C) and high temperature (500-800°C) for applications in carbon capture from power plants and hydrogen production.

Energy: High purity natural gas from shale gas/biomass via hydrocarbon/acid gas permeation.

Pharma and Manufacturing: Purification of products from organic processes of relevance to pharma and fine chemical companies using membrane processes, including organic solvent nanofiltration, for example catalysts and product separation and active pharmaceutical ingredient (API) separation from impurities.

Water: Water permeation and purification using nanofiltration,forward and reverse osmosis, and dual proton and oxygen ion conduction.