About Us

The towing tank at Newcastle University stands as a symbol of the institution’s long-standing commitment to marine engineering and hydrodynamics research.

Origins and Construction (1950)

The tank was conceived and built in 1950 under the leadership of Professor Lennard C. Burrill, a propeller design expert and then Professor of Naval Architecture, with technical support from Dr. Arnold Emerson. Funding was secured from the University along with support from local and national maritime industry partners.

The facility was constructed in the Armstrong Building, specifically in a former hydraulics laboratory that had become vacant after the Civil Engineering Department moved to the newly built Cassie Building. The main tank structure was made of reinforced concrete, lined with waterproof materials, and finished with a mahogany capping for durability and aesthetics. It measured 37 meters in length, 3.7 meters in width, and had a water depth of 1.25 meters.

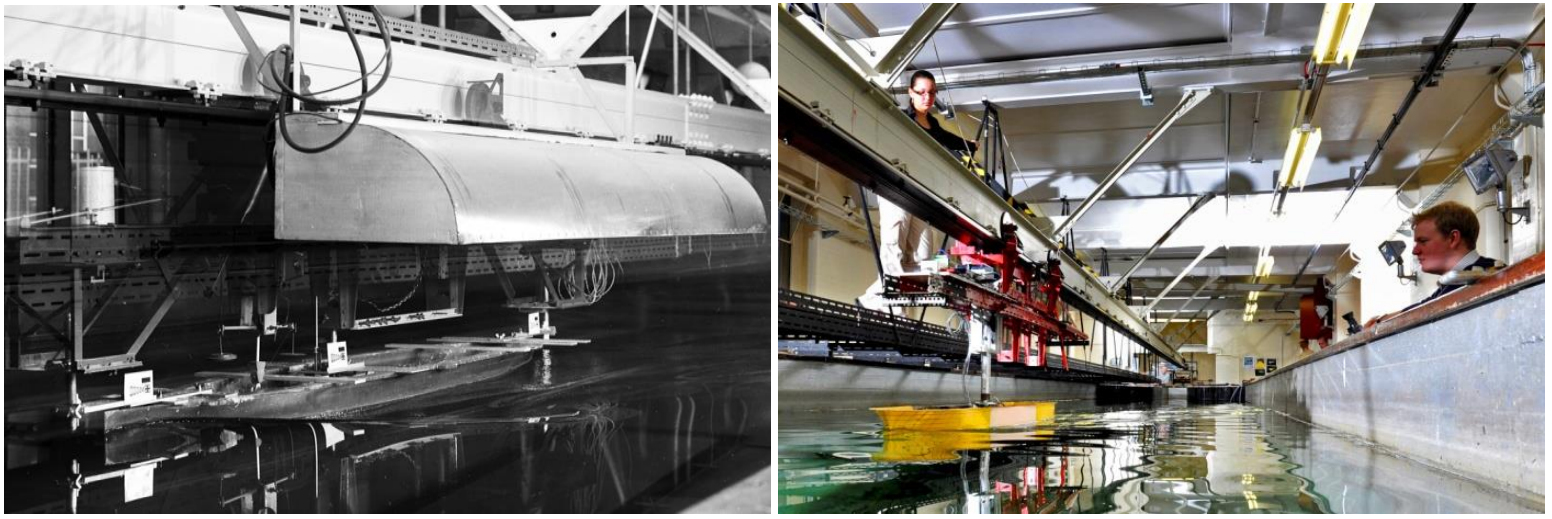

Carriage System

A key feature of the towing tank is its monorail carriage system. The system was originally used by Vickers Shipbuilders as part of a demonstration at the 1951 Festival of Britain in the Dome of Discovery. After the festival, the system was donated to the University. However, to meet the precision standards needed for scientific research, the rail was machined to high tolerances and mounted on a rigid girder system to prevent any deformation due to building settlement or vibration. The carriage itself is unmanned and electrically driven via a pulley system and thyristor-controlled motor.

Wave Generation and Evolution

Initially, the tank was used primarily for demonstration purposes, but it quickly became a hub for serious research and consultancy. In the 1960s, the first wave maker—a pneumatic system—was installed. While it produced accurate waves, it was difficult to control and often flooded the lab.

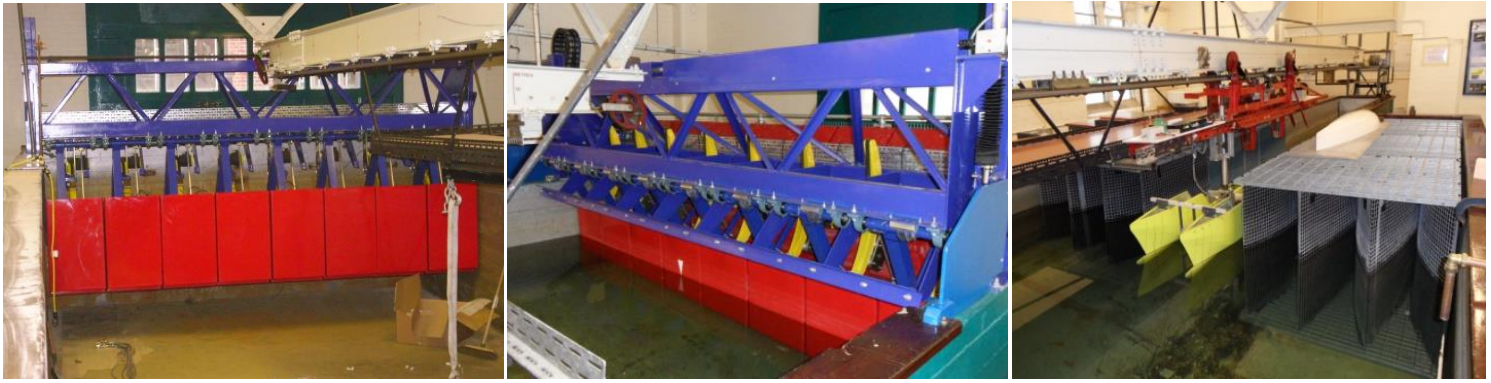

To address these issues, in 1973, the University installed the first rolling seal wave maker in the UK, allowing much better control over wave generation, including the ability to simulate shallow water conditions. This system served well for over 30 years until it was replaced in 2008 with a displacement piston-type wave maker, funded through the SRIF3 (Strategic Research Infrastructure Fund) programme.

The new system, manufactured by Edinburgh Design, features eight paddles and precise control via PC-based software. It can simulate a range of regular and random wave spectra, including Pierson-Moskowitz, JONSWAP, Bretschneider, and Neumann. This wave maker eliminated issues like friction and unwanted back waves, enhancing the tank's research capability.

In tandem, the old parabolic wave beach was replaced with a vertical wedge-type absorption beach, constructed using modern materials such as polyether foam and geo-textiles, achieving high wave absorption efficiency with minimal reflections.

Current Capabilities

Today, the towing tank has evolved into a cluster of marine hydrodynamics facilities. These facilities have been used for a wide variety of research projects, model testing for commercial applications, and as an essential educational resource in resistance, propulsion, and seakeeping experiments. Despite its size limitations, it is considered one of the most versatile hydrodynamic test facilities in the UK.

Reference

Atlar, M. (2011). Recent upgrading of marine testing facilities at Newcastle University. AMT’11. Newcastle upon Tyne, UK: 4-6.